Scanner-Tester and FEX Software

Scanner-Tester

Description

The Scanner-Tester simulates both the infrared (IR) and ultraviolet (UV) radiation found in burner flames. These features make it a unique tester for Fireye compact flame scanners and flame scanners with UV tube. Equipped with a 9 VDC block battery, mobile operation is also possible up to four hours with the new version 02-04. The unit has an evaluation of the 4-20mA analog output of the compact flame detectors.

Modulated flicker frequencies of a burner flame are simulated and the intensity can be preset for the IR and/or UV range. The display of the scanner tester can be used to check the states of the flame and fault relays of compact flame detectors and the drop-out time of the flame relay.

The Scanner-Tester has two possible operating modes:

1. Battery operation:

This operation is for a mobile test of compact flame detectors at a plant. In this case, the flame detector must be supplied by the power supply on the plant side.

2. Mains operation:

Here, a compact flame detector can be supplied with 24VDC (terminals 1 and 2) directly via the side terminal strip using a connection cable.

FEX Fireye Explorer Software

Description

Fireye Explorer is a software program for real-time data acquisition and recording in conjunction with Fireye flame scanners with communication capability. These are the 95DSS3 (Insight II) and 95UV/IRS4 (Insight IV) series compact flame scanners.

This software can be used to program the compact flame scanners and provides extremely useful data in real time to the user. This allows the user to draw conclusions about flame stability and flame evaluation.

The displays are all pre-configured and the information is provided in a simple and understandable manner. Data storage allows subsequent analysis through the use of historical data.

Features

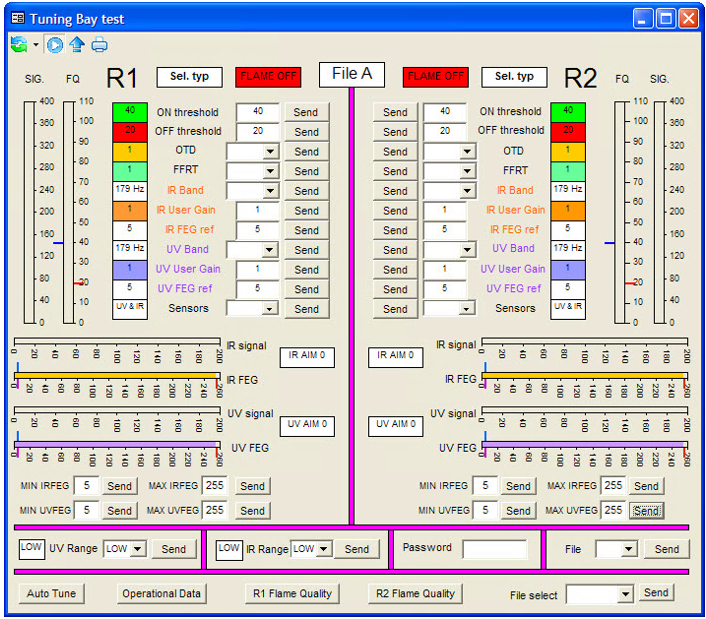

Information is presented in different formats according to the data displayed. Analog signals such as Flame Quality (FQ) are displayed as a bar graph, the range and switching points are clearly shown and provide immediate information on the status of the flame signal without knowing the status of the digital signals. These displays, called “faceplates”, can be individually placed on the screen in the form of small windows according to their relative position on the boiler. This simplifies the identification of flame problems and at which burner this is happening.

An event list provides on-screen information on predetermined events such as the change from flame status ON to OFF and vice versa.

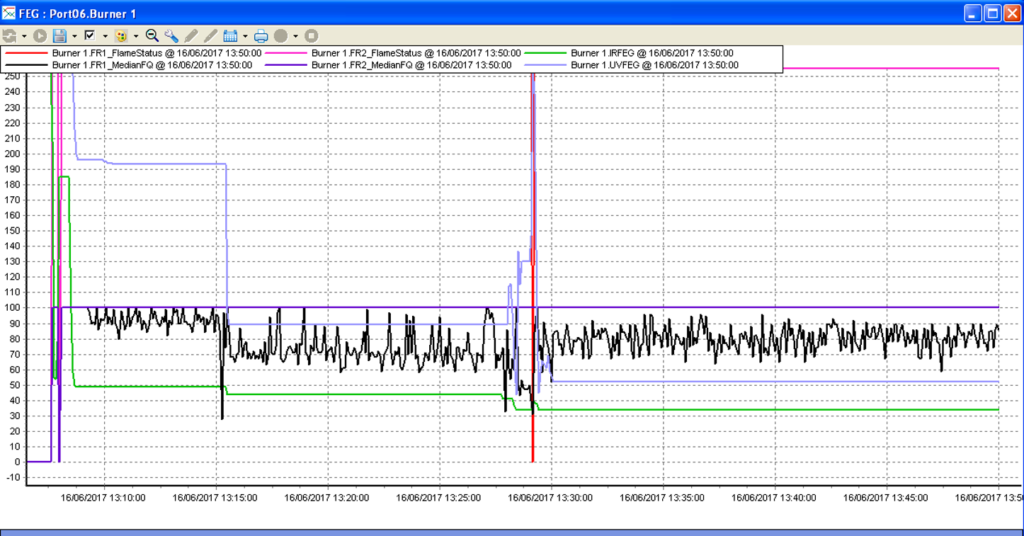

For more detailed information on how the scanner is responding to the flame, the analyzed data can be displayed in a graphical format. This data can be saved and recalled as needed. Recording of signal strength, response, gain, etc. is an integral part of the software and is suitable for real-time data acquisition and data analysis of events that have already occurred.

The FEX software provides an OPC server interface via Ethernet to transfer the flame scanner data to a supervisory control system (DCS). The data is transferred to the DCS as long as the flame detector is online.